02, 2021

by oreelaser

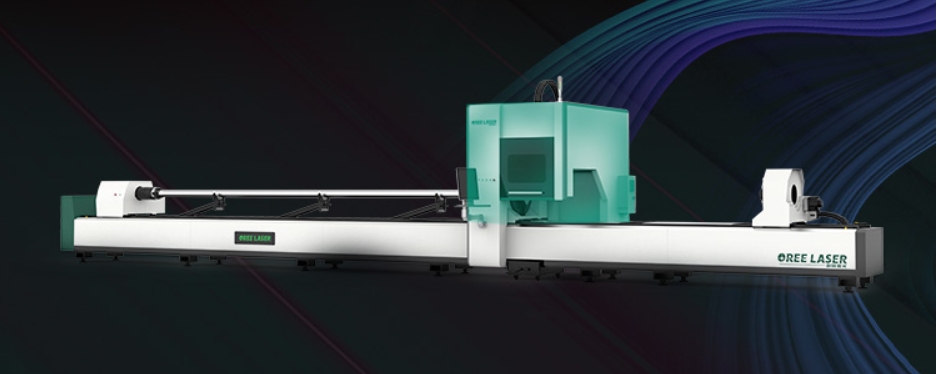

Real zero Tailing | Three-chuck tube fiber laser cutting machine launch!

Oree’s new TS series three-chuck laser pipe cutting machine, innovating the double-chuck clamping method, adopts a three-chuck design, which can maintain the front, middle, and rear three-point clamping support of the pipe in real-time and can correct the pipe bending problem. The relative cutting efficiency of some pipes is 5%-10% higher than that of the double chuck pipe cutting machine. The pipe cutting is true ‘zero tailing’, helping customers to achieve fast, high-quality, and low-cost production and processing.

Ingenious design

Semi-enclosed visual protective cover

Rocker type industrial computer

Vertical lift door

Operation warning light

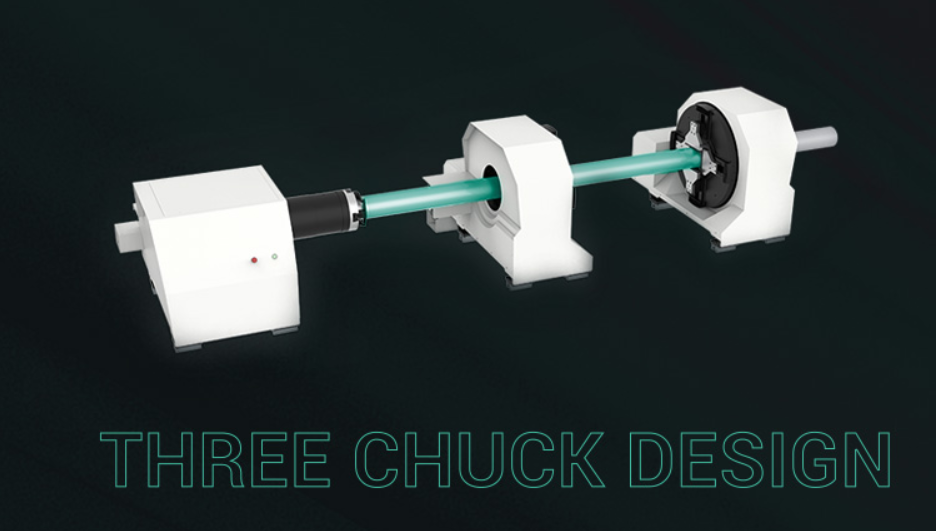

Innovative three-chuck design, stable clamping & stable cutting

One-key self-centering, fast clamping, rapid cutting

Three-point clamping to correct pipe bending, prevent inertial shaking and ensure cutting accuracy

The clamping force of the chuck can be adjusted according to the wall thickness of the pipe, which is convenient and efficient

The rear chuck brakes quickly to ensure pipe cutting accuracy

Real zero Tailing

The diameter of round tube: 15mm-220mm

The side length of square tube: 15mm-150mm

High pipe load, the maximum single pipe weight is 300kg

Clamping square tube, round tube, oval tube, flat tube, triangle tube, I-beam, and other materials without pressure

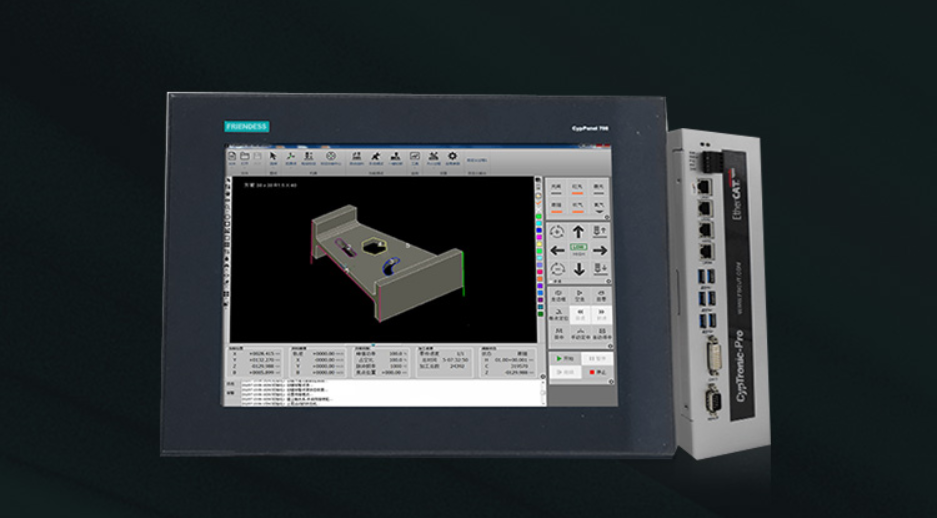

FSCUT5000 Three-Chuck Tube Cutting System, intelligent control

Real-time compensation of pipe center deviation, reducing pipe clamping requirements and higher efficiency;

The pipe has higher perforation accuracy and more accurate cutting.

Based on the bus real-time system and integrated control, the pipe corner-cutting is faster;

The corner following is more stable, and the cutting quality is more reliable.

3D tube nesting software TubesT, meet your production needs

TubesT is a 3D tube nesting software for the TS series. From parts drawing and modification, full type compensation, strategic nesting to report generation, using TubesT will meet and exceed your production needs.

Intelligent Nesting

Flexible Common Line

Quick Import

Drawing Modification

Nesting Report

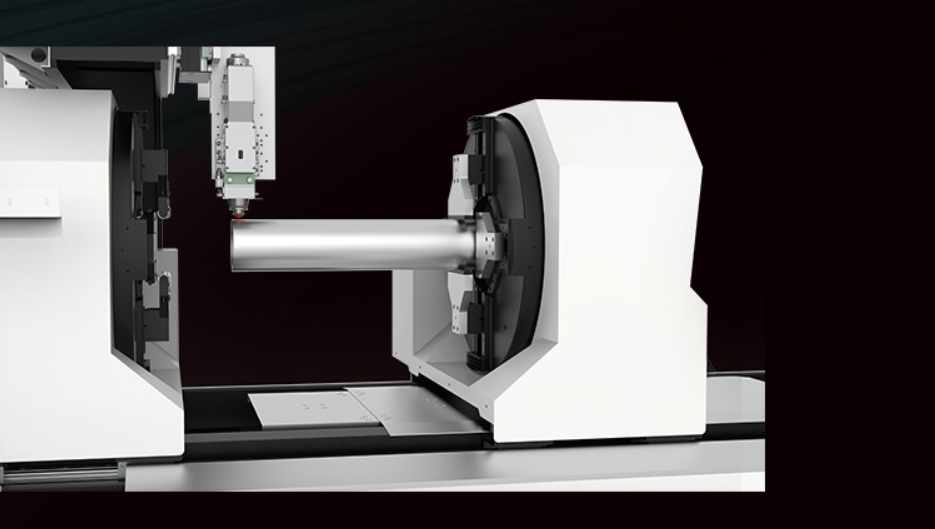

Double-sided follow-up support device

Double-sided support device

It can reduce processing errors, ensure uniform force on the entire metal pipe, and improve cutting accuracy.

The chuck and support device are highly synchronized

Real-time feeding to prevent the reduction of cutting accuracy due to pipe distortion.

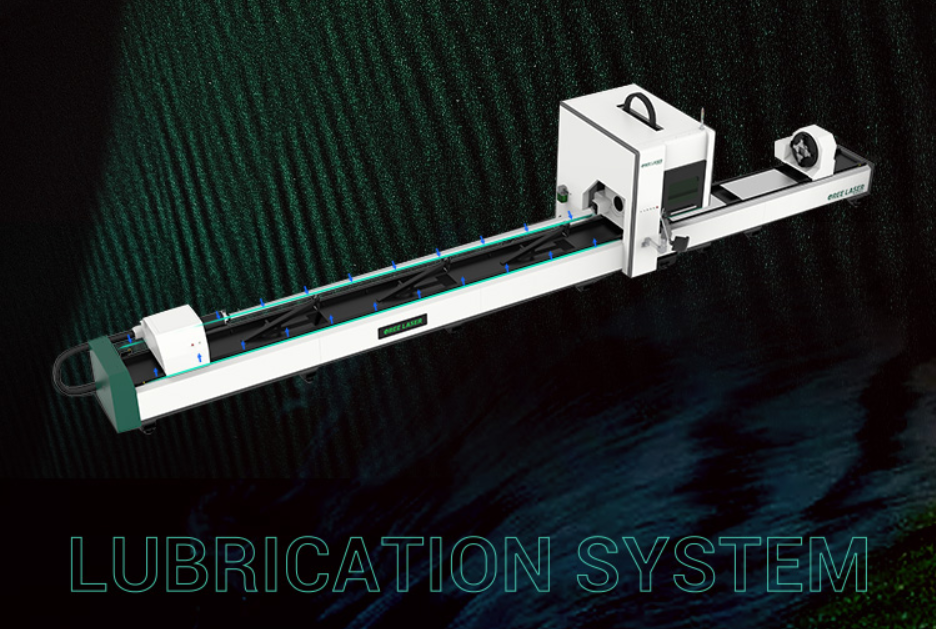

Automatic Lubrication System

The number and time interval of automatic lubrication can be manually set according to the length of equipment use;

Automatic lubrication for guide rails, sliders, gears, racks, etc., without manual lubrication;

The waste lubricating oil can be recycled and treated centrally.

Technical Parameters

Model | TS6020 |

Diameter of round tube | φ15mm-φ220mm |

Side length of square tube | 15*15mm-150*150mm |

maximum single pipe weight | 300kgs |

Pipe processing length | 6m |

X/Y axis positioning accuracy | ±0.03mm |

X/Y axis repeat positioning accuracy | ±0.03mm |

X/Y-axis Maximum Simultaneous Positioning Speed | 100m/min |

Maximum acceleration | 1G |

Input power | 380V/50-60Hz |

Laser Output Power | 1000W/1500W/2000W/3000W/4000W/6000W |

Professional Laser Cutting Machine Manufacturer - OreeLaser